Sanitary Diaphragm Valves

LPSInc.net is proud to feature Aquasyn Sanitary Valves

Aquasyn has developed the ultimate high purity valve for the bioprocess and pharmaceutical industries, setting a new standard in engineering, design, and manufacturing. The innovation and high quality of this new Aquasyn product provides the customer with a series of excellent benefits. The complete product line includes special innovations such as the valbow and the sample bottle assembly valve.

Aquasyn valves feature Tork-TiteTM Feet diaphragm stops; high quality body material that exceeds the industry standards; all stainless internal components; unique UltrazTM USP diaphragm material; machined stainless steel bonnet; smooth operating, high temperature, plastic handwheels; customized solutions; and high quality actuator feet.

Benefits include much longer life cycles, lower maintenance costs, excellent delivery capabilities, customized combinations, easy to configure and order, state of the art surface finishes (inside and out), and best cost of ownership.

| Further Information | Ordering Information | Valve Technical Data |

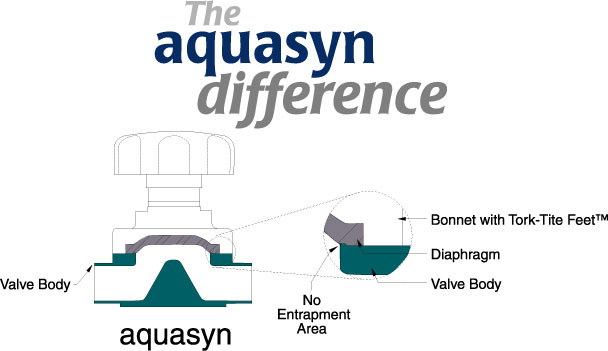

Tork-TiteTM Feet set Aquasyn valves apart from the competition

Further Valve Details

Leading Innovative Products and Solutions, working directly with Aquasyn, LLC, provides high quality, innovative diaphragm valve solutions to optimize your process requirements. Aquasyn manufactures a complete line of Two Way, Sterile Access, Zero Static Tee, Use Point valves which incorporate the following standard features to assist in assuring process purity:

- All Valve bodies machined from 316L bar stock, are self draining, and feature ASME-BPE compliant chemistry with full traceability

- Controlled sulfur content (0.005-0.010) and ferrite content (< .5%)

- Patented Tork TiteTM bonnet feet and integral machined sealing ridge on the valve body insure controlled compression, zero leakage diaphragm seal with less potential for media entrapment than competing designs

- Sizes 1/4" through 3" (4" and 6" introduction planned for 2005...)

- High quality 'purpose built' stainless steel autoclaveable bonnets and stainless steel/thermoplastic actuators insure long, trouble free cycle life

- Precision molded diaphragm material options: UltrazTM, EPDM, PTFE/EPDM, Viton, Silicone. (USP Class VI, and FDA Title 21-177compliant) with complete lot traceability

- Fast Delivery on MRO and Project orders

- Exotic materials available, such as AL6XN, Hastelloy, Titanium, and more!

- Aquasyn produces the widest variety of custom products in the industry including Valbow, Sample Bottles, manifolds, and many more!

- 3-D / CAD Design capability

Whether your requirements dictate just one special assembly or 1000, please call us with your special needs and let us show what we can do for you...